Lagoon Systems

Reduce overall maintenance and extend the capacity and life span of your lagoon without dredging.

Water Quality:

- Increase lagoon DO (dissolved oxygen)

- Decrease ammonia, total nitrogen, and phosphorus

- Decrease lagoon BOD (biochemical oxygen demand)

- Decrease FOG (fats, oils, and grease)

- Decrease TSS (total suspended solids)

Sludge Quality:

- Digest lagoon sludge and prevent new sludge from collecting

- Expand your lagoon’s treatment capacity without service interruption

Turnover improvement:

- Improve turnover results by digesting unwanted sludge

- Minimize bio-mat and surface coverage

- Speed up bio-mat reduction

Appearance:

- Control algae and odor

- Reduce unwanted plant growth

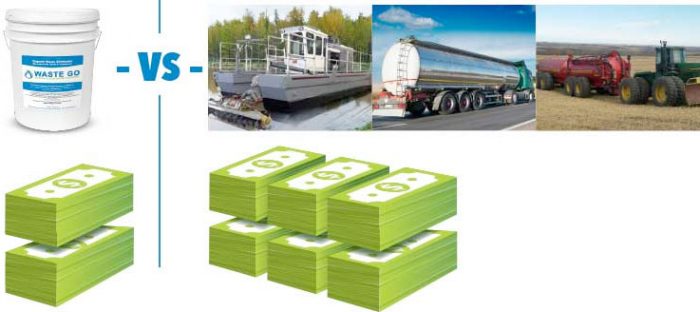

Rejuvenate your lagoon system for 1/3 the cost of mechanical without any interruption of service!

Lagoon Stats derived from 30+ years of Testimonials

• 90% reduction of grease

• 90% reduction of TSS

• 90% drop of BOD

• 90% reduction of odor

• 85%+ reduction of sludge

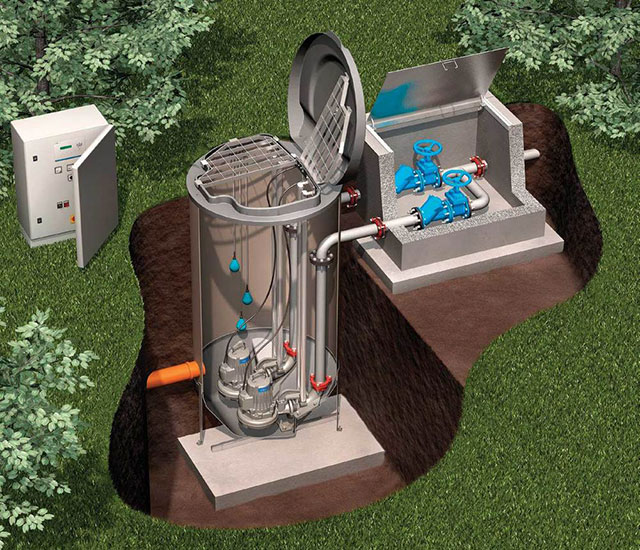

Lift Stations

Waste Go eliminates grease in lift stations which allows level controllers to operate effectively. It reduces the amount of sludge in the well which reduces the cleaning maintenance required. Regular Waste Go maintenance treatments, provide clean running pumps which reduce electrical costs for pumping, maintenance costs and repair costs to pumps.

Lift Station Stats derived from 30+ years of Testimonials

• 90% reduction of grease

• 90% reduction of solid

• 90% reduction of odor

• 95% reduction of Hydrogen Sulfide gas

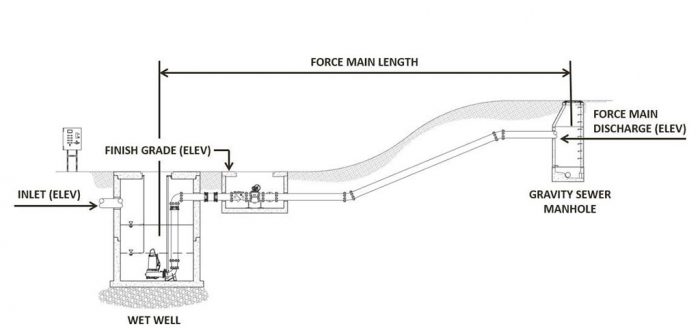

Gravity & Force Mains

In Gravity and Force Mains, grease and soaps become bound together. Waste-Go breaks this bond by neutralizing and digesting the grease. This eliminates rancid grease and the acidic conditions which causes hydrogen sulfide production.

Waste Go eliminates grease and prevents new build up which maintains the cross-sectional area of the sewer main, reducing pumping costs.

Where sulfide odours are a problem, Waste-Go reduces sulfide production and is economical compared to the cost of conventional treatment methods such as hydrogen peroxide and other chemicals.

By reducing sulfide production, Waste Go which reduces sulphuric acid production and the deterioration of concrete pipes and corrosion problems throughout your system.

Gravity & Force Main Stats derived from 30+ years of Testimonials

• 90% reduction of grease

• 90% reduction of odor

• 95%+ reduction of Hydrogen Sulfide Gas

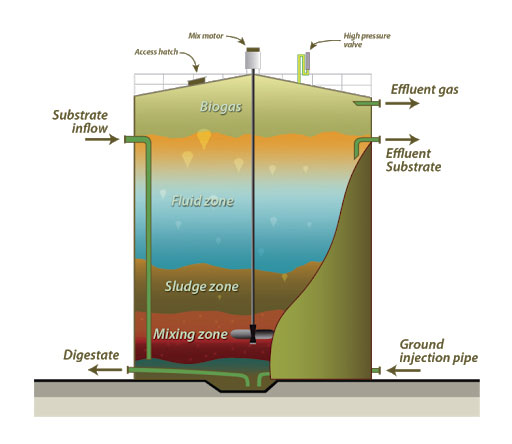

Wastewater Treatment Plants

WASTE GO solves your problems within the Treatment Plant!

Are any of these problems familiar?

- Exceeding design capacity

- Odor control costs skyrocketing

- Insufficient retention time in secondary aeration basins

- Foaming digesters

- Scum layers in anaerobic digesters

- Grease plugs in lines

- Hydraulic overloading

- Seed source needed after digester cleaning

- Grease balls in digesters

In Anaerobic & Aerobic digesters, Waste Go applied directly to the U-Tubes will:

- Eliminates scum blanket, foam and digests grease

- Increases volatile solids reduction

- Improves gas production

- Improves settling characteristics

- Improves mixing

- Controls odors by directly attacking the cause

- Prevents grease buildup in sludge transfer lines

- Stabilizes pH, volatile acids and alkalinity. Digester operating parameters respond by becoming linear and less likely to vary

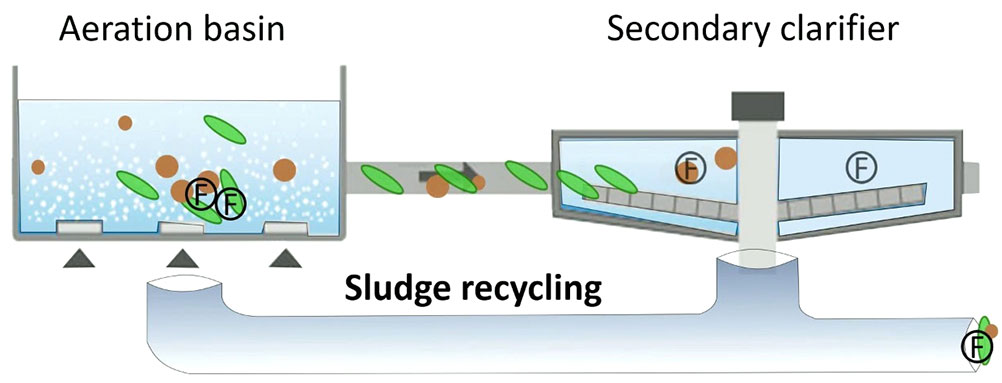

In Aeration Basins and Clarifiers:

- Provides faster recovery after hydraulic overload (washout)

- Helps overcome toxic stress conditions and regain normal activity

- Provides the most efficient microbes and catalysts to speed up volatile solids digestion

- Eliminates grease build up on freeboard surfaces and grating

The advantages of WASTE GO are clear!

- 100% SAFE to all living organisms – NSF Certified

- Decreases solids removal by reducing 80%+ solids

- Prevents cleanouts and hauling from digesters that have become “dead”

- Almost eliminates FOG’s (fats, oils and grease)

- Produce a better quality sludge

- Economical – A fraction of the cost of mechanical

- Saves on odor control costs

- Saves on labor

- Saves costs on chlorine and eliminates the need for grease solvents and hydrogen peroxide

- Seed your digester and eliminate sludge transport

Retention Ponds

Retention Ponds serve a purpose for low lying areas but can lead to unpleasant odours, dangerous health issues (toxic algae blooms), unwanted insect infestation and even flooding if not maintained properly.

Waste Go cost effectively treats Retention Ponds, to eliminate algae, odours and unwanted pests by eliminating their food source. By digesting organic buildup caused by wildlife, Waste Go helps provide clog free release pipes from creating flood conditions during major storms.

By treating Retention Ponds with Waste Go, you also ensure safe release back into natures water ways while keeping local residents happy.